As power networks continue to expand in urban, industrial, and utility environments, the demand for safe, durable, and efficient underground cabling systems has increased significantly. Concentric cable plays a vital role in low- and medium-voltage power distribution where mechanical protection, electrical safety, and long service life are required.

HNBF Power, a global manufacturer of overhead conductors and power cables, supplies high-quality concentric cables designed to meet international utility and infrastructure standards, supporting reliable power delivery across diverse applications.

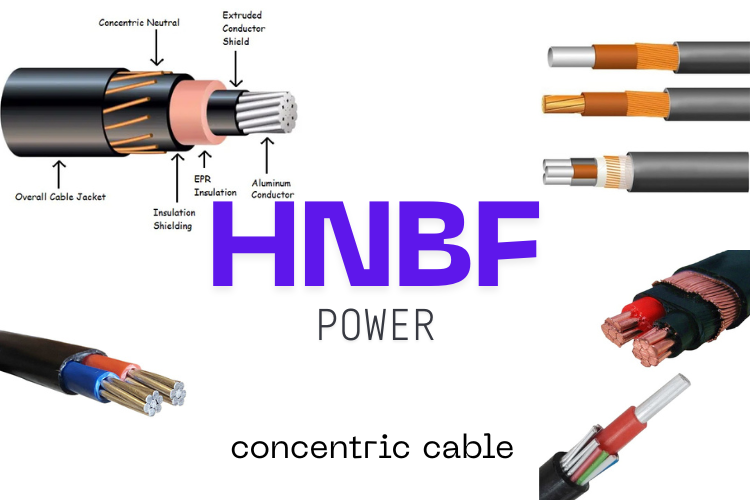

What Is a Concentric Cable?

A concentric cable is a type of power cable in which the neutral or grounding conductor is arranged concentrically around the insulated phase conductor. These concentric conductors are typically made of copper or aluminum wires, helically wrapped over the insulation layer.

This design provides:

-

A balanced electrical return path

-

Improved fault current handling

-

Enhanced mechanical protection

-

Reduced electromagnetic interference

Concentric cables are commonly used in underground distribution systems, service drops, street lighting networks, and industrial power installations.

Key Construction Features of Concentric Cables

Central Phase Conductor

The core conductor is usually aluminum or copper, designed to carry the primary load current. Its size and stranding are selected based on voltage rating and current capacity.

Insulation Layer

High-quality XLPE or PVC insulation ensures electrical safety, thermal resistance, and long-term stability under varying load conditions.

Concentric Neutral Conductors

Multiple small aluminum or copper wires are applied concentrically over the insulation. These serve as:

-

Neutral return conductors

-

Grounding paths

-

Fault current conductors

Outer Sheath

An outer PVC or PE sheath provides resistance against moisture, chemicals, abrasion, and soil corrosion, making the cable suitable for direct burial or duct installation.

Applications of Concentric Cable in Power Networks

Concentric cables are widely used across utility and industrial sectors due to their robust design and safety benefits.

Underground Power Distribution

Utility companies rely on concentric cables for low-voltage and secondary distribution networks in residential and commercial areas.

Service Entrance and Service Drops

The concentric neutral design ensures safe grounding and stable voltage supply to end users.

Industrial Facilities

Factories, plants, and infrastructure projects use concentric cables where grounding reliability and fault protection are critical.

Street Lighting and Public Infrastructure

Their durability and electrical balance make them ideal for municipal power systems.

Advantages of Using Concentric Cable

Improved Electrical Safety

The concentric neutral provides a continuous grounding path, reducing the risk of electric shock and equipment damage.

Enhanced Fault Current Capacity

Multiple neutral strands allow effective dissipation of fault currents during short-circuit conditions.

Long Service Life

High-quality insulation and corrosion-resistant materials ensure reliable performance in harsh underground environments.

Simplified Installation

The integrated neutral design eliminates the need for separate grounding conductors, reducing installation complexity and labor costs.

Why Choose HNBF Power Concentric Cables?

HNBF Power manufactures concentric cables with a strong focus on utility-grade reliability, electrical performance, and compliance with international standards. Our production capabilities cover a wide range of conductor sizes, insulation types, and neutral configurations to meet specific project requirements.

Key strengths include:

-

Advanced manufacturing and quality control processes

-

Aluminum and copper conductor options

-

Compliance with IEC, ASTM, and utility specifications

-

Custom designs for EPC contractors and power utilities

With experience in supplying power transmission and distribution products globally, HNBF Power supports engineers and procurement teams with consistent quality and technical expertise.

Technical Considerations When Selecting Concentric Cable

When specifying concentric cable for a project, engineers should evaluate:

-

Rated voltage and current capacity

-

Neutral conductor size and material

-

Installation method (direct burial or duct)

-

Environmental conditions such as moisture and soil chemistry

-

Applicable utility or regulatory standards

Working with an experienced manufacturer like HNBF Power ensures the selected cable meets both electrical and mechanical performance requirements.

FAQs About Concentric Cable

1. What is the main purpose of concentric neutral conductors?

They provide grounding, carry unbalanced currents, and safely dissipate fault currents in power distribution systems.

2. Are concentric cables suitable for direct burial?

Yes, when designed with appropriate insulation and outer sheath materials, concentric cables are well-suited for underground direct burial installations.

3. What materials are used for concentric neutral wires?

Concentric neutrals are typically made from aluminum or copper, depending on conductivity and project specifications.

4. How does concentric cable improve system safety?

The continuous neutral layer reduces grounding resistance and enhances protection against electrical faults.

5. Can HNBF Power customize concentric cable designs?

Yes, HNBF Power offers customized concentric cable solutions based on voltage rating, conductor size, and utility requirements.

Partner with HNBF Power for Reliable Concentric Cable Solutions

Choosing the right concentric cable is essential for safe, efficient, and long-lasting power distribution. HNBF Power combines manufacturing expertise, technical knowledge, and global supply capability to deliver concentric cable solutions tailored to utility, industrial, and infrastructure projects.

Contact HNBF Power today to discuss your technical requirements and receive customized concentric cable solutions engineered for dependable power delivery.